We have two press brakes: Vartek 220 tons with a useful length of 4100 and 7 axes, and Vartek 100 tons with a useful length of 2600, equipped with a hydraulic crowning system for precise and constant bends, with a video-graphic control for simulations and optimization of bending sequences.

The machines are equipped with an automatic back gauge to perform precise standard or conical bends, accessorized with matrices and punches of various types and shapes to meet various bending requirements: radiused, flanged, clinched, etc.

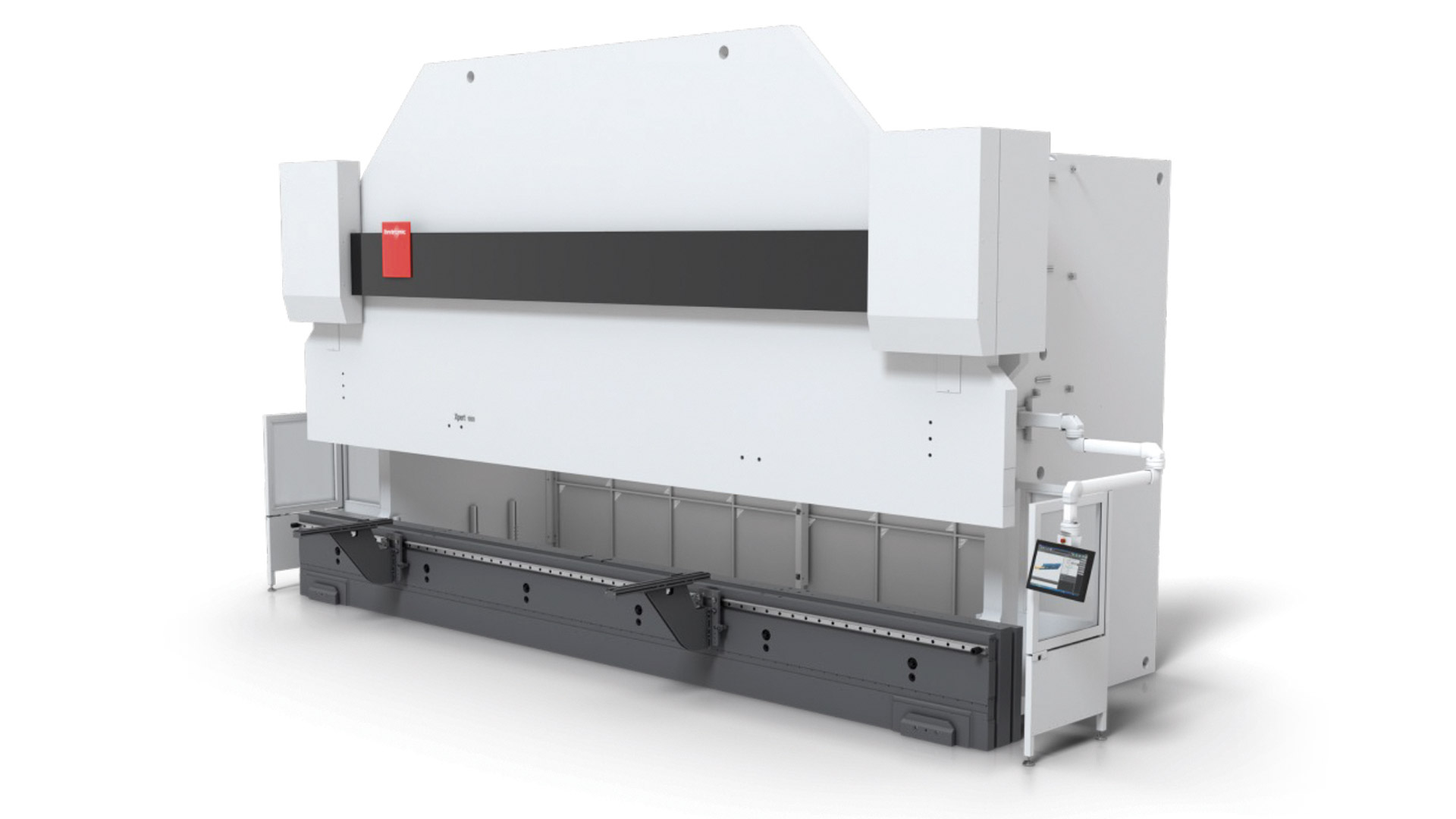

Bending of large-sized sheets with exceptional performance

Since April 2023, we have equipped ourselves with a new sheet metal press brake, a Bystronics model Xpert 500, with a bending capacity of up to 6 m length and 500 tons of power. It is equipped with support trays and an extractor for creating closed profiles.

Our Xpert 500 is outstanding for extreme applications and large dimensions. Quality is guaranteed – from the first to the last piece.

Xpert 500 delivers optimal performance even in complex bending processes and for different materials of varying thickness and quality. This allows you to complete your orders more quickly and flexibly.

Bending trials are no longer necessary. Precision from the first bend.

Accurate sheet metal bending is crucial for cost reduction, especially when dealing with extremely large and long-bent elements. Xpert 500 saves operators from challenging trials and corrections, thanks to intelligent assistance functions such as the LAMS angle measurement system and the material curve generator. The machine is equipped with a side extraction system, allowing us to create fully closed boxes, a system widely used for most requests in the aerial platforms sector.

Baldoni s.r.l. | P.I. IT03042610364 | Credits: www.excellentmarketing.it