Recently, Baldoni S.r.l has expanded its production process by incorporating precision mechanical machining with the aim of meeting the continuous and growing market demand for a “finished” product.

To fulfill these requirements, the company has invested both financially and technically, introducing into its machinery lineup a DOOSAN VCF850L-SR machining center with Fanuc 31i-B5 CNC and an Edge Cam CAD-CAM station for tool programming and management

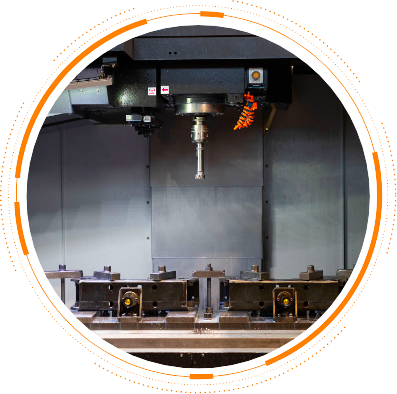

5-axis mobile gantry Machining Center – DOOSAN VCF850LSR with swiveling head and integrated rotary table.

X-axis Travel: 3000 mm

Y-axis Travel: 850 mm

Z-axis Travel: 800 mm

B-axis Travel (head swiveling): ± 110°

C-axis Travel (table rotation): ± 360°

Cone Size: ISO40

High-pressure internal tool cooling: 60 bar

In addition to the recent acquisition of the DOOSAN VCF850LSR, Baldoni S.r.l has also purchased a new 3-axis DOOSAN DNM 6700L Machining Center. This machine is primarily used for the machining of small-sized components, drilling and threading of plates and flats, as well as deburring/chamfering of parts intended for robotic welding.

In addition to the recent acquisition of the DOOSAN VCF850LSR, Baldoni S.r.l has also purchased a new 3-axis DOOSAN DNM 6700L Machining Center. This machine is primarily used for the machining of small-sized components, drilling and threading of plates and flats, as well as deburring/chamfering of parts intended for robotic welding.

Baldoni s.r.l. | P.I. IT03042610364 | Credits: www.excellentmarketing.it