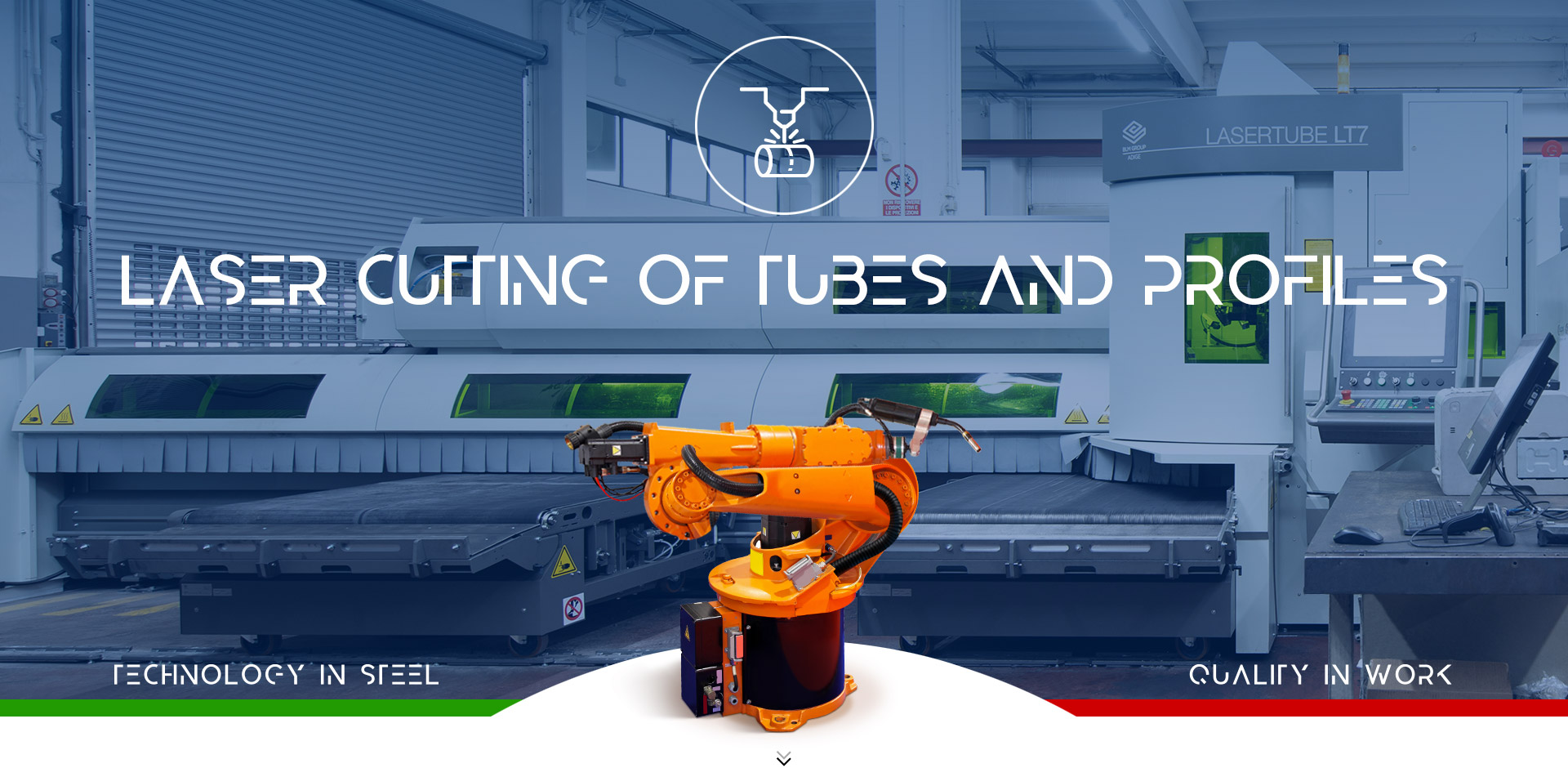

Since May 2007, our company has expanded its machinery fleet with a fourth tube laser: LT8 – LT7 – LT5 – LTfiber.

The new LT8 and LT7, equipped with a tilting cutting head, allow for 3D processing on both open profiles and special sections (including concave ones). With our 4 systems, we can meet any request, covering a range of tubes from 10 to 220 mm in diameter and a bar weight that can go up to 37 kg/m.

The high quality of production is complemented by additional devices that enable us to manage the correct positioning of welding and self-correct any geometric imperfections in the profile.

The tube laser, with its numerous applications, offers significant benefits, ranging from material and processing savings to the assembly of components. It allows the creation of joints and references to eliminate welding centimeters and reduce assembly equipment costs.

LaserTube LT Fiber

Ecco le principali specifiche di questi 2 nuovi impianti:

NEW LT 7

Processable profiles up to 152.4 mm

Bar weight up to 25 kg/m

Maximum loading length 8.5

Maximum unloading length 6.5

4 kW fiber laser source

Automatic adjustments for cuttable materials: iron, stainless steel, aluminum, copper, brass.

With a capacity of 5000 Kg, it can be installed on both the front and rear sides of the machine.

A short-piece discharge belt, available in the basic configuration, provides an additional unloading position for pieces up to 500 mm.

Fully integrated into the discharge device, it extracts processing residues during cutting, leaving the internal surface perfectly intact.

Available down to a minimum diameter of 20 mm.

Welding search to detect the weld bead and allow proper orientation of the bar before processing.

Tracking support devices, essential for effectively and accurately working with lighter tubes and/or supporting heavier sections.

| DESCRIPTION | VALUE |

|---|---|

| Thickness S235-S355-S700: | 15 mm |

| Stainless Steel Thickness: 304-316-430: | 10 mm |

| Aluminum Thickness: Alloy 6060: | 6 mm |

| Minimum Bar Length: | 2500 mm |

| Maximum Bar Length: | 8500 mm |

| Maximum Bar Weight: | 37 Kg/m |

| Maximum Loading Bed Capacity: | 5000 kg |

| Maximum Unloading Length: | 6500 mm |

| BARS SIZE | VALUE (min-max) |

|---|---|

Round Tubes:

|

Ø10 - Ø220 mm |

Square and Rectangular Tubes:

|

10 - 220 mm |

Flat Bars:

|

5x20 mm - 15x200 mm |

Angle Bars and "L" Shapes:

|

15x30 mm - 200x200 mm |

"U," "C," and UPN Bars:

|

20x20 mm - 200x200 mm |

Oval, Semi-Oval, and Elliptical Tubes:

|

Ø10 - Ø220 mm |

Isosceles Triangle Tube:

|

15x30 mm - 40x70 mm |

| Sections for Fixtures: |

1A - 1B - 1C - 2A - 2B - 2Z - 10A 10B - 11A - 11B - 11C - 14A - 15A 15T - 15Z - 16A - 16B - 16D 16T - 16Z - ML - MT - MZ |

| Sections for Gates: | SF 1/B - SF 2/B - SF 3/B - SGF 9 - SGF 10 |

Baldoni s.r.l. | P.I. IT03042610364 | Credits: www.excellentmarketing.it